WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

This Angle roll forming machine is an automatic cold-forming device specifically designed for the efficient and precise production of L-shaped (corner) studs, which are crucial components in building partition and ceiling systems. It perfectly meets the demand for high-quality light gauge steel studs in Peru's booming construction and renovation market.

Core Product Advantages

* Specialized Focus, Efficient Production: The equipment is exclusively optimized for L-shaped studs. It automates the entire process from coil decoiling and leveling to continuous roll forming and fixed-length cutting, ensuring precise product dimensions, consistent strength, and far superior production efficiency compared to traditional methods.

**Why is it Suitable for the Peruvian Market?**

* Matches the Local Construction Boom: In Peru, especially in major cities like Lima, commercial and residential renovation and retrofit projects are continuously growing. The standardized L-shaped studs produced by this machine are key components in light gauge steel stud partition systems, ensuring stable market demand.

*Enhances Local Manufacturing Competitiveness: It helps local metal fabrication plants or building material suppliers in Peru achieve independent production of key building components, reducing reliance on imported finished products and improving supply chain efficiency and profit margins.

* Environmental and Operational Adaptation*:

* User-Friendly Operation: Comes with a Spanish operation interface and training materials to lower the learning curve.

* Service Support: Can leverage technical service networks or partners in South America to provide timely installation guidance and after-sales support.

**Successful Application Scenarios**

The L-shaped studs produced by this equipment are widely used in:

* Lightweight partition and ceiling systems in office buildings, hotels, and shopping malls.

* Interior finishing of public buildings such as hospitals and schools.

* Zoning and renovation in residential projects.

| Formed Material |

GI/GL, PPGI/PPGL |

| Thickness |

1.35-2.0mm |

| Decoiler |

Manual decoiler(will give you as free) |

| Roller station | 8rows |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5KW |

| Control system Language | English, Spanish,etc.(Support multiple languages) |

| Voltage | 220V, 60HZ, 3Phase |

| Forming speed | 45m/min(The speed depends on the shape of the tile and the thickness of the material.) |

Why Choose Us

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

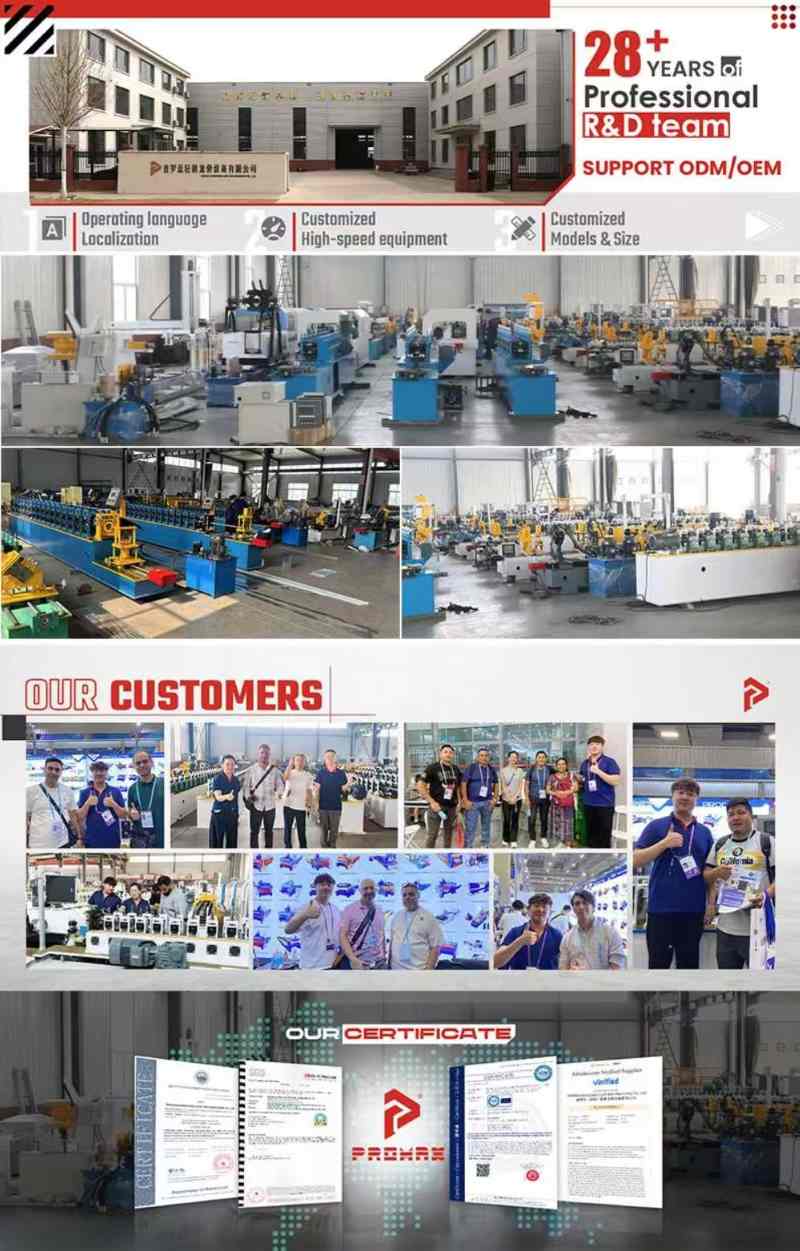

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.