WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

In many modern factories, the concept of C-shaped stud roll forming machines is often closely associated with precision cold roll forming technology. However, in our view, a truly exceptional C-shaped stud roll forming machine should, at its core, inherit the forging spirit of machines like the C41 series air hammer—pure, solid, and full of power. It is not merely a piece of equipment but a philosophy regarding materials and quality.

The C41 series air hammer, a classic symbol of the mechanical forging era, is renowned for its robust structure and steady, reliable striking force. It represents the most direct wisdom in metalworking: using pure and controllable impact energy to reshape the internal structure and external form of metal, thereby granting it greater strength and toughness. This profound understanding and shaping capability of the metal's "constitution" is the genetic origin of any high-end metal forming equipment.

The philosophy we uphold is that a modern C-shaped stud roll forming machine should not merely be a "bender" of coil stock but rather a "forger" of architectural skeletons. While the traditional C41 hammer strengthens metal through impact, our C-shaped stud roll forming machine evolves this "forging logic" to a continuous and precise level:

* Internalization of Force: The impact force of the C41 is transformed here into continuous, progressive, and uniform forming pressure applied by dozens of roller stations. Each roll pass acts like a precise forging strike, ensuring that while the strip steel changes shape, its internal grain structure is optimized, resulting in C-shaped studs with high rigidity, minimal springback, and precise dimensions.

* Revolution in Precision: We inherit the traditional equipment's relentless pursuit of stability and elevate it to the micron level. The machine's core high-strength cast iron frame and precision bearing system ensure stability comparable to forging dies is maintained even under long-term high-load operation, eliminating product deviation.

* Continuation of Toughness: Workpieces forged by the C41 are known for impact resistance. Our stud roll forming machine, through optimized roll pass design, avoids hidden damage that can occur during rapid forming. This results in studs that are not only dimensionally standard but also possess excellent overall toughness and fatigue resistance, becoming a reliable safety skeleton within buildings.

It is precisely this design philosophy, originating from forging equipment, that elevates our C-shaped stud roll forming machine beyond ordinary cold-forming standards. It produces not just profiles that meet national standards but architectural skeletons with "forging-grade" intrinsic quality:

* Higher Material Utilization and Structural Efficiency: Increased strength of the formed studs allows for the potential of optimal material configuration while meeting the same architectural mechanical requirements.

* Ultimate Installation Compatibility: Precise dimensions and consistent profiles enable on-site construction to proceed as smoothly as assembling precision components, significantly reducing labor costs and errors.

* Bearing Safety and the Test of Time: Solid quality, from the inside out, ensures the long-term stability and safety of partition wall and ceiling systems, silently safeguarding the life of the building.

Therefore, when you see our C-shaped stud roll forming machine, it is not just an efficient production line but can also be regarded as a precision "stud forging press" for the architectural era, which inherits the soul of C41 forging. We believe that only by integrating classic manufacturing wisdom with modern technology can we build the solid foundation that will truly support the architecture of the future

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12 rows(As your requirement) |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5Kw |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase |

| Forming Speed | 40-50m/min(The speed depends on the shape of the tile and thickness of the material.) |

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

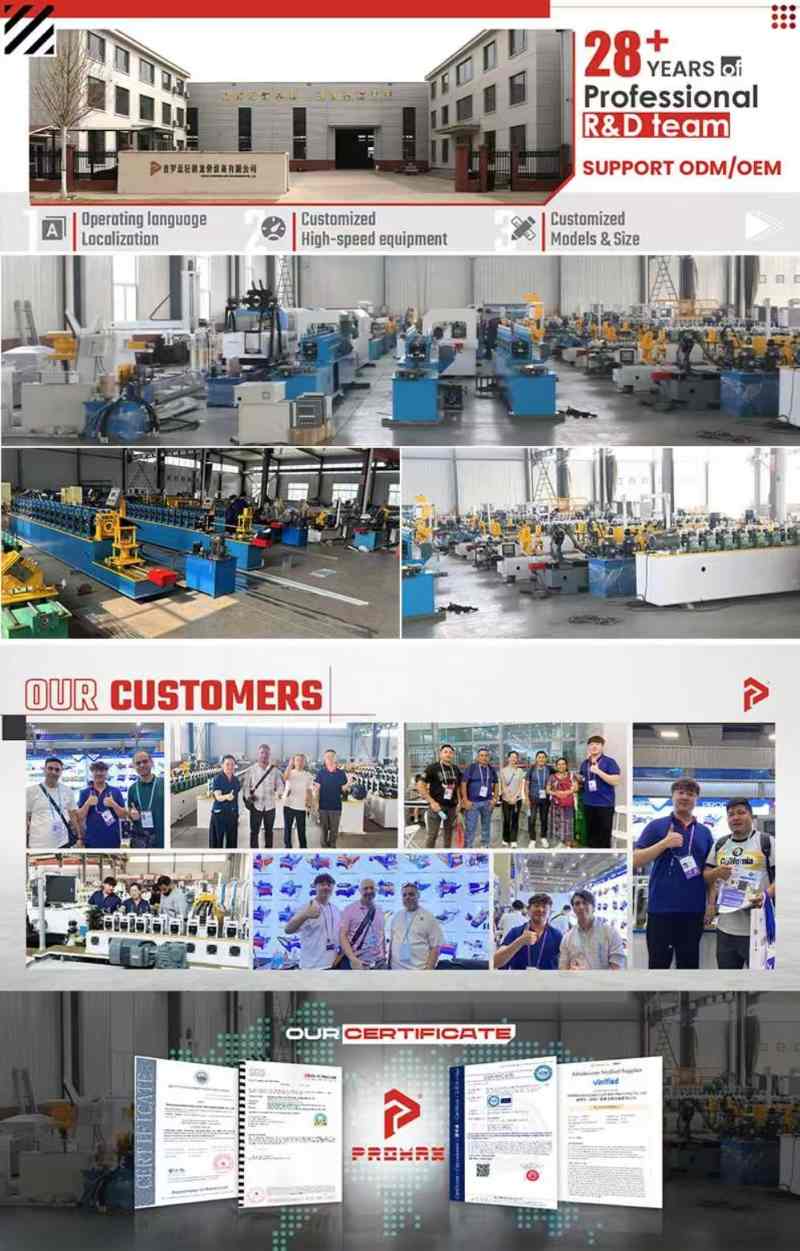

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.