WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Flexible, Versatile, and Ruggedly Reliable: The Track Roll Forming Machine Tailored for the Chilean Market

Facing the diverse and multi-scale demands of construction projects in Chile, we bring you a solution that combines flexibility, cost-effectiveness, and ruggedness into one—the Manual Changeover U-shaped Stud Roll Forming Machine. Designed specifically for small to medium-sized building material factories, metal workshops, and construction teams seeking efficient production and cost control, this machine is your powerful partner in market expansion.

Core Advantage: One Machine, Multiple Uses—Adapting Flexibly to Market Changes

The standout feature of this equipment is its Manual Quick-Changeover System.

*Versatile Functionality: By changing out different sets of forming roller dies, a single host machine can produce U-shaped light gauge steel studs in multiple sizes and specifications. This perfectly adapts to the varied needs of the Chilean market, from interior partition walls and ceilings to light building frameworks.

*Investment Efficiency: There is no need to purchase separate entire machines for each stud specification, significantly reducing initial equipment investment and long-term maintenance costs. This is particularly suitable for production models with diverse product lines but moderate individual batch sizes.

*Easy Conversion: After simple training, operators can complete die set changes in a relatively short time, greatly reducing downtime and enhancing production scheduling flexibility.

Design & Performance: Safeguarding Stable Production

While emphasizing flexibility, the core performance of the machine does not compromise.

*Rugged Frame: Utilizes a high-strength steel plate welded forming frame that undergoes stress-relief treatment, ensuring stable precision and resistance to deformation during long-term operation.

*Quality Drive System: Durable components are selected for the core bearing and gear transmission systems, ensuring smooth and stable operation even in areas of Chile that may experience voltage fluctuations.

*User-Friendly Operation: Features an intuitively designed, simple control panel and adjustable feeding guides, lowering operational difficulty and reducing over-reliance on highly skilled workers.

Why is it Suitable for the Chilean Market?

1. Adapts to Project Diversity: Whether for large commercial renovations in Santiago or small to medium-sized residential construction across various regions, this machine can quickly adapt to produce the required stud specifications.

2. Reduces Operational Costs: For areas with varying power infrastructure, its stable mechanical structure and low energy consumption design are practical advantages. The manual changeover system also saves on the maintenance costs associated with complex automation systems.

3. Built to Last: Key components are reinforced for continuous production, offering strong durability and reducing the hassle of frequent maintenance.

Our Service & Support

We understand the concerns of long-distance equipment procurement and therefore provide:

*Clear operation and maintenance manuals in English/Spanish.

*Critical spare parts kits to ensure timely replacement of wear-prone components.

*Installation guidance and operational training available via video conferencing.

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 10 rows |

| Diameter of shaft | 50mm solid shaft |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5KW |

| Control system Language | Chinese, English, Spanish,etc. |

| Voltage | 380V, 50HZ, 3Phase |

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

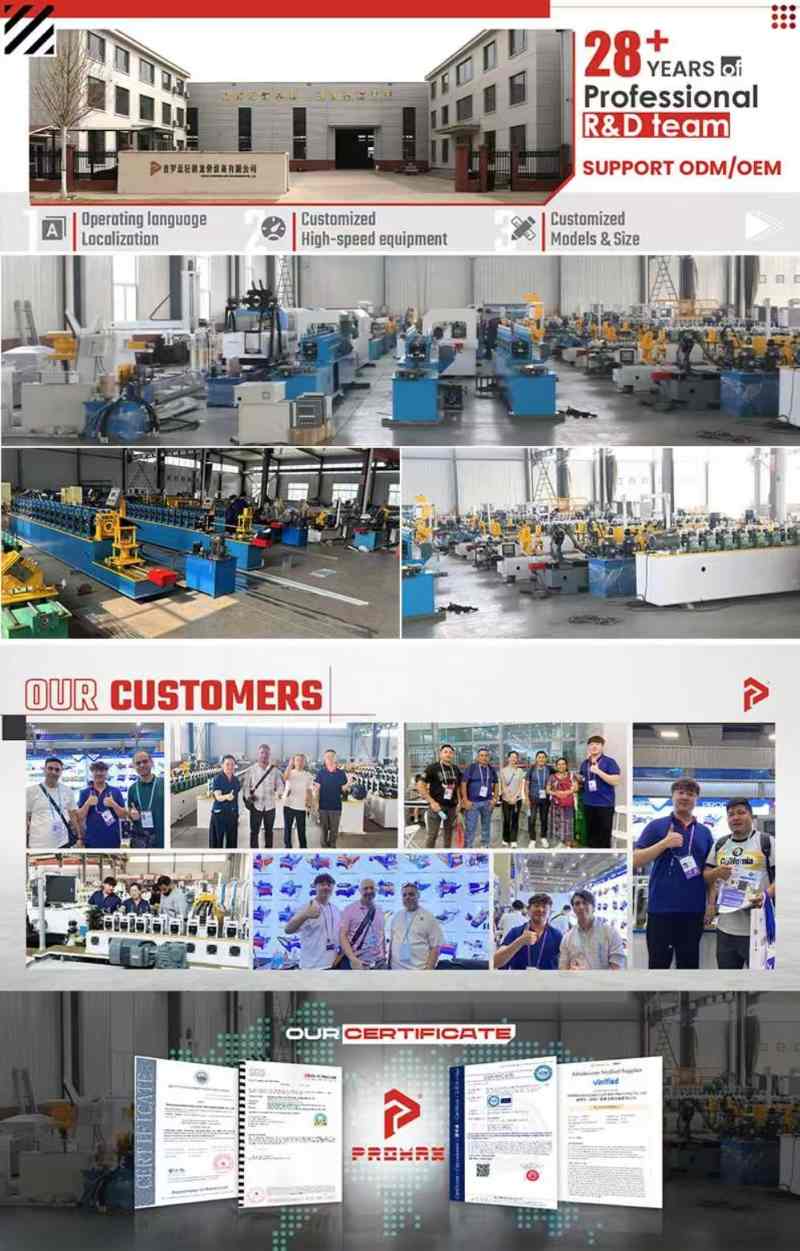

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.