WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Product Positioning and Core Advantages

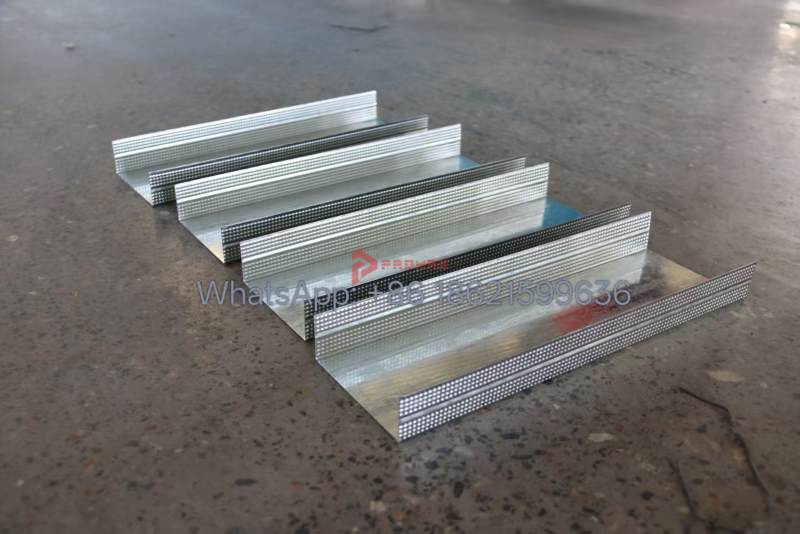

The track roll forming machine, designed for the high-standard U.S. construction market, is a fully automatic, high-precision roll-forming equipment. It specializes in producing the crucial U-shaped (channel) studs for building ceiling systems, partition wall edging, and load-bearing systems. This machine is strictly designed according to U.S. building material industry standards, aiming to help local manufacturers, metal fabricators, and builders enhance their competitiveness and meet the growing market demand for high-quality, high-consistency light gauge steel components.

This equipment precisely addresses the stringent requirements of the construction market, especially in commercial renovation and prefabricated building:

1.Aligns with Mainstream Applications and a Vast Existing Market: U-shaped studs are standard components for ceiling systems and the top/bottom tracks of drywall partition walls in U.S. non-residential buildings (such as office buildings, shopping malls, hospitals, and schools). The enormous stock of commercial buildings and high-frequency renovation projects create stable and sustained demand.

2.Meets the Trend of Localized Production and Rapid Response: Facing supply chain fluctuations, more contractors are leaning towards sourcing from local manufacturers. This equipment enables clients to respond quickly to project orders, providing products with lengths, special hole patterns, or markings, offering significant logistics and flexibility advantages compared to overseas imports.

3.Reduces Overall Costs Through Intelligence: High automation reduces reliance on highly skilled technicians, and stable high output dilutes the unit cost. Intelligent production scheduling and material management functions help U.S. clients maintain strong competitiveness in a market with high labor costs.

4.Comprehensive Localized Support and Service: We provide full English operation interfaces, technical documentation, and safety guidelines aligned with OSHA principles. Through our network of partners in North America, we are committed to providing timely on-site technical support, adequate spare parts supply, and professional process training.

Primary Application Scenarios

The U-shaped studs produced by this equipment are the cornerstone of the following applications:

*Commercial Ceiling Systems: Serves as main/secondary hanging studs for various exposed or concealed ceilings.

*Light Gauge Steel Frame Walls: Acts as the top and bottom tracks for walls, used in conjunction with C-shaped studs.

*Pipeline and Cable Tray Supports: Functions as the main component of the support system.

*Prefabricated Building Modules: Serves as the edge framing in modular building units, ensuring fast and precise on-site assembly.

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 10 rows |

| Diameter of shaft | 50mm solid shaft |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5KW |

| Control system Language | Chinese, English, Spanish,etc. |

| Voltage | 380V, 50HZ, 3Phase |

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

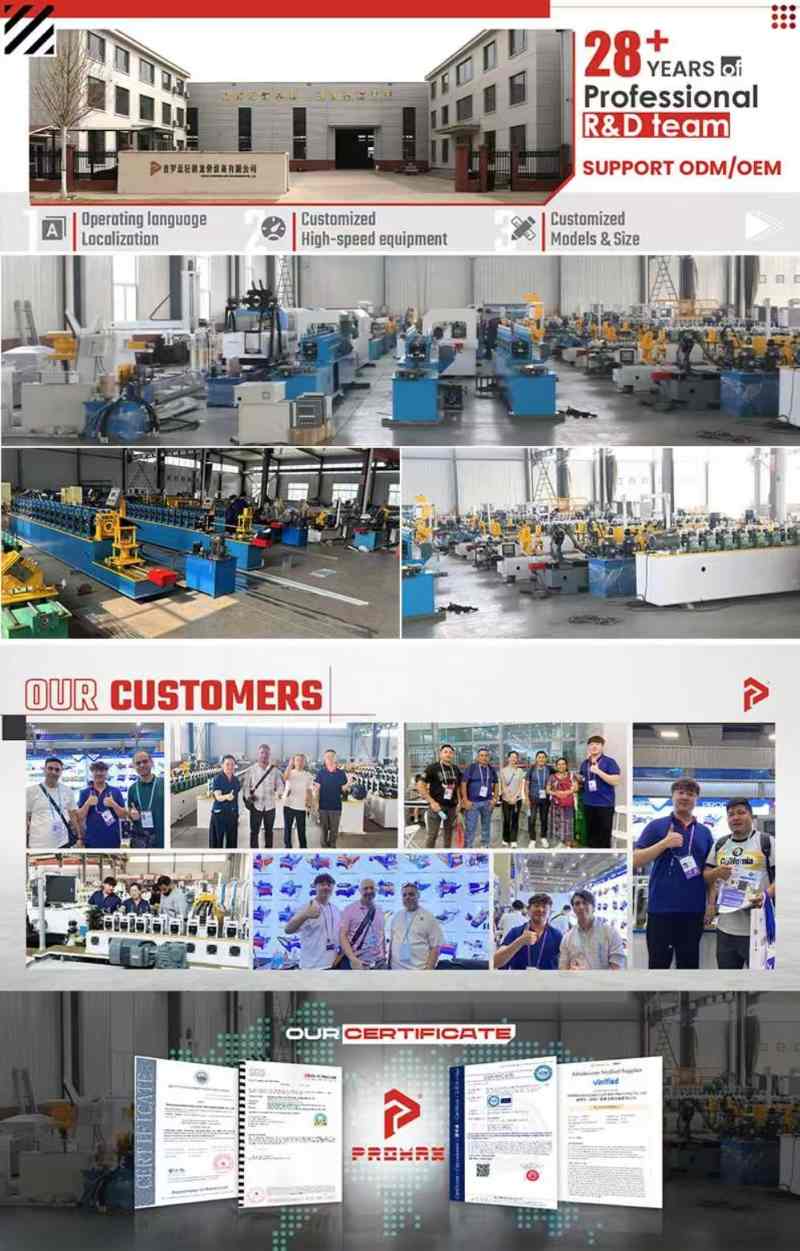

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.