WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

To meet Morocco's growing demand for high-end building skeletons, we break through traditional cold-forming concepts to introduce this innovative machine that integrates classic forging philosophy with modern precision forming technology—the Used metal stud machine for sale with a C41-grade forging core. It does not merely "bend" steel; instead, it instills exceptional strength and reliability into your construction projects with a forging-like resolve.

Core Philosophy: Infusing the Soul of C41 Forging into Stud Manufacturing

The C41 series air hammer symbolizes the ultimate pursuit of intrinsic material enhancement from the metal forging era. We translate this pursuit into the core philosophy of modern manufacturing and embed its essence into the design of this C-shaped stud machine:

*From Impact Force to Sustained Force: The intense, instantaneous impact energy of forging is transformed into the "continuous, uniform, and controllable" precise pressure applied through dozens of roller stations during the forming process. Each roll pass acts like a micro-forging operation, shaping not only the form but also optimizing the steel's internal structure.

*Pursuing Intrinsic Strength and Toughness: The goal is not just forming but, akin to forging, striving to enhance the final product's overall toughness, fatigue resistance, and extreme dimensional stabilit, producing C-shaped studs that can be called "forging-grade."

Technical Realization:Excellent performance Customized for Morocco

1. Forging-Grade Rugged Frame: The machine's core frame adopts an ultra-heavy-duty design philosophy and material standards analogous to forging equipment, ensuring deformation resistance far exceeds that of ordinary machines under long-term high-load operation, providing the foundation for consistently producing top-tier products.

2. Precision Roll Forming System: The roll forming system is optimized kinematically,imitate forging principles of uniform force application to ensure smooth material flow and precise, consistent cross-sectional dimensions of the studs. This perfectly meets the stringent material precision requirements of high-end construction projects in Morocco.

3. Localized Environmental Adaptation:Aim at the potential humidity and specific working conditions in Morocco's coastal areas, critical moving parts and structural surfaces of the machine undergo enhanced anti-corrosion and wear-resistant treatments, ensuring the equipment's long-term durability and low maintenance costs in the local environment.

Unique Value Created for the Moroccan Market

*Defining New Standards for High-Quality Construction: Provides structural performance surpassing ordinary cold-formed studs, making it particularly suitable for high-rise buildings, large public facilities, and projects demanding higher safety and longevity. It helps contractors build a reputation for top-tier quality.

*Excellent Long-Term Return on Investment: While the initial investment may be slightly higher, the machine's extremely low failure rate, longer service life, and the higher market value and demand for the products it produces will yield a significantly superior long-term return on investment.

*Technological Empowerment for Local Industry: Empowers Moroccan manufacturers to enter the high-end building materials market, escape homogenized competition, and gain premium pricing power and customer loyalty with differentiated "forging-quality" products.

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12 rows(As your requirement) |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5Kw |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase |

| Forming Speed | 40-50m/min(The speed depends on the shape of the tile and thickness of the material.) |

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

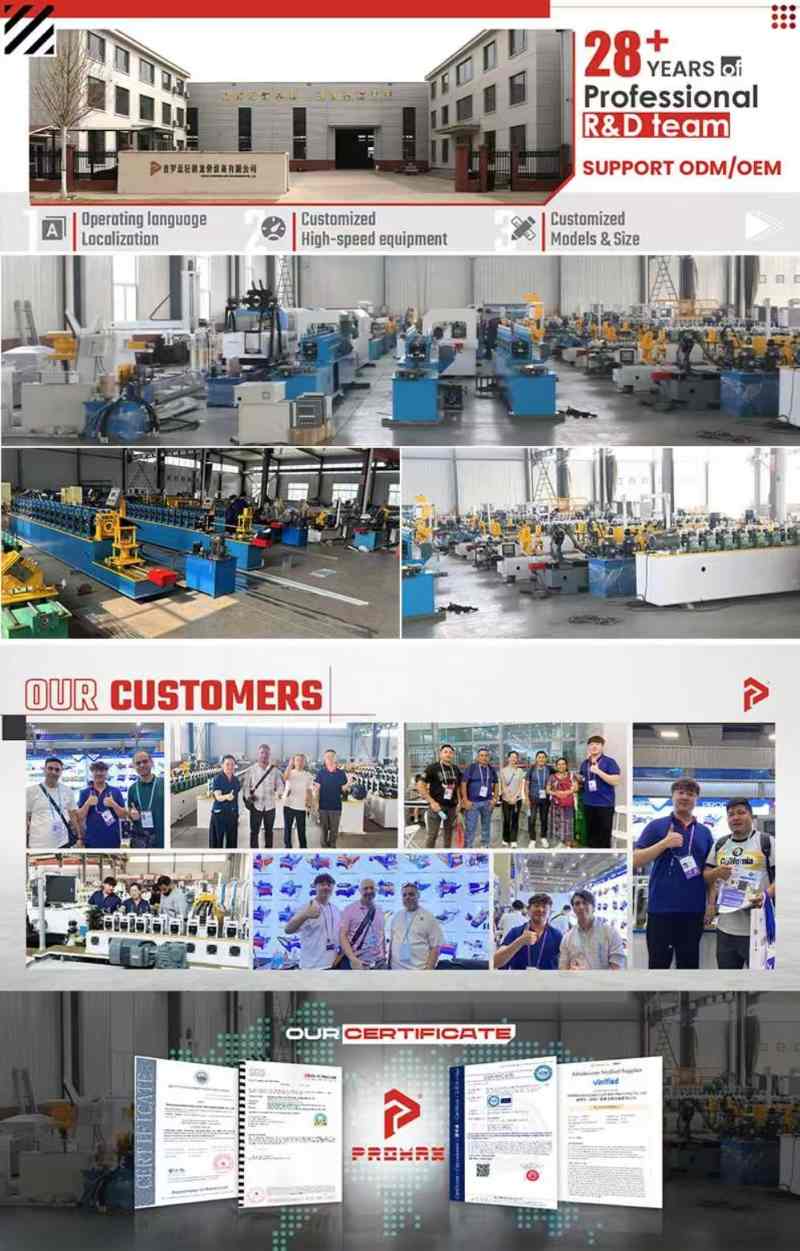

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.