WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

**Product Positioning and Core Advantages**

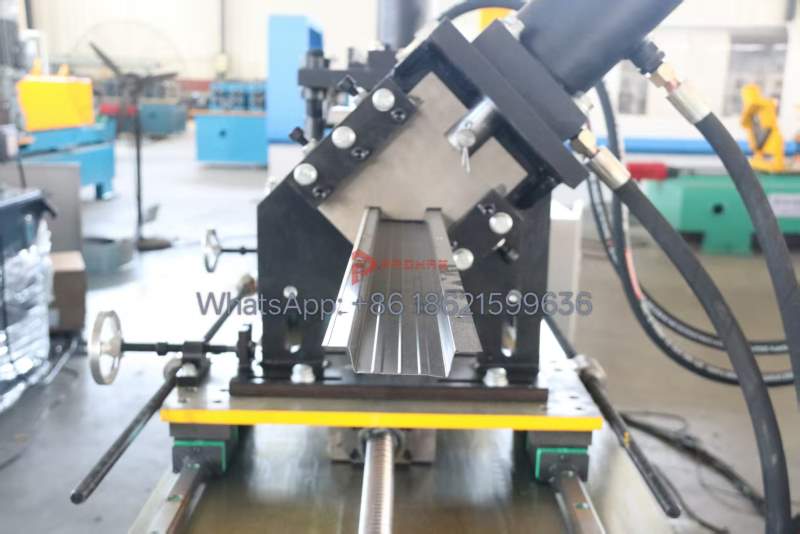

The hat channel roll designed specifically for the modern construction market in Morocco, is an intelligent equipment used for the efficient production of unique Omga-shaped (Ω-shaped) light-gauge steel studs. Omga-shaped studs generally offer superior load-bearing capacity, bending stiffness, and overall stability compared to traditional C-shaped and U-shaped studs, making them particularly suitable for construction scenarios with higher structural requirements.

**The core advantages lie in its high strength and versatility:**

* Excellent Structural Performance: The unique cross-section of Omga-shaped studs allows for more effective stress distribution, providing outstanding compressive and lateral bending resistance. This makes them an ideal choice for high-end partition walls, floor linings, and heavy-duty ceiling systems.

*Production Flexibility and Intelligence: This machine utilizes advanced servo drives and a PLC control system for precise control of the forming process. By quickly changing specific roller sets, a single machine can produce Omga-shaped studs in various sizes and can be flexibly integrated with C/U-shaped stud production lines to adapt to diverse order requirements.

*Efficient and Stable Output: The fully automated process, from coil feeding and precise positioning to continuous roll forming and high-speed fixed-length cutting, ensures high dimensional accuracy and batch consistency, significantly boosting production efficiency.

**Market Adaptability Analysis for Morocco**

This equipment is highly aligned with Morocco's current and future construction development needs:

**Meeting Market Upgrade Demands**: With the acceleration of Morocco's urbanization and continued investment in social housing, tourism facilities, and commercial infrastructure under the **"2022-2026 National Development Strategy"**, the demand for high-performance, high-standard building materials is growing. Omga-shaped studs can meet the material standards for higher-grade hotels, office buildings, shopping centers, and high-end residential projects.

**Addressing Local Climate and Regulations**:

* Climate Adaptation: Key electrical components feature dust-proof and heat dissipation designs, and transmission parts have anti-corrosion treatments, enabling adaptation to the dry/dusty conditions of southern Morocco and the humid coastal climate of the north.

**Enhancing Local Industry Competitiveness**: It provides metal fabrication plants or building material manufacturers in Morocco with the capability to produce high-end stud products. This enables them to shift from competing in traditional building materials to the high-value-added product sector, reducing dependence on imported high-end components and increasing project profit margins and market competitiveness.

**Comprehensive Localized Support**: Through our joint service system established with local partners in Morocco, we can provide rapid **installation commissioning, operational training, spare parts supply, and technical response**, ensuring long-term stable operation of the equipment and maximizing return on investment for our clients.

**Primary Application Scenarios**

The Omga-shaped studs produced by this equipment are widely used in:

* **High-end Commercial and Public Buildings**: Such as partition walls, ceilings, and floor systems in five-star hotels, Grade A office towers, and large shopping malls.

* **Institutional Construction Projects**: Public facilities like hospitals, schools, and stadiums that have higher requirements for sound insulation, fire resistance, and load-bearing capacity.

* **Industrial and Warehouse Buildings**: Can be used for wall and roof linings in light industrial factories.

* **High-Quality Residential Projects**: Partition walls and reinforced ceilings in high-end apartments and villa projects.

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12 rows(As your requirement) |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5KW |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase(customizable) |

| Forming speed | 40-50m/min(The speed depends on the shape of the tile and the thickness of the material) |

Why Choose Us

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

About Us

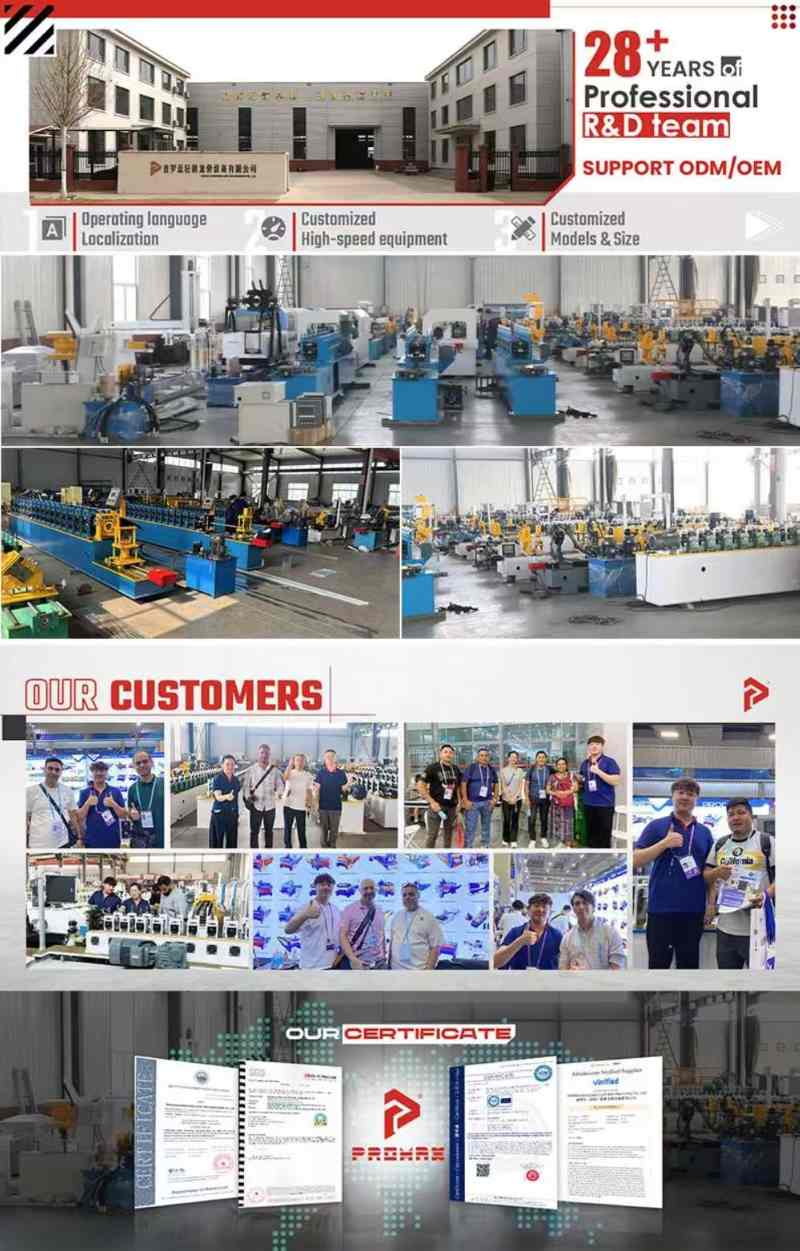

Haixing Industry Group – Precision Roll Forming Experts Since 1996

With nearly three decades of expertise, Haixing Industry Group specializes in designing and manufacturing high-performance roll forming machines and automated production lines. Trusted by over 5,000 clients in more than 150 countries, we turn custom requirements into reliable production solutions.

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.