WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

**Core Advantages: A Fusion of Superior Performance and Intelligent Production**

*Exceptional Structural Strength: The furring channel machine cross-section effectively disperses stress, providing outstanding compressive and lateral bending resistance. It is particularly suitable for **ceiling systems, partition walls, and floor linings** that require high load-bearing capacity or long spans.

*Efficient and Flexible Production: The equipment employs advanced servo drives and a PLC control system to ensure forming accuracy and speed. By quickly changing specific roller dies, it can flexibly produce Omega-shaped studs in various sizes and easily adapt to galvanized steel coils of different thicknesses, meeting diverse order requirements.

*Stable, High-Quality Output: Integrating automatic decoiling, precision leveling, continuous roll forming, high-speed fixed-length cutting, and counting, the fully automated process guarantees extremely high dimensional consistency and excellent surface quality, significantly boosting production efficiency and material utilization.

This equipment precisely aligns with the current construction industry opportunities in Ethiopia, which are dominated by infrastructure and urbanization:

1. Aligning with National Development Trends: The Ethiopian government is vigorously promoting infrastructure, industrial parks, and modern housing construction, with rapid urban development in the capital, Addis Ababa. There is strong market demand for high-performance building materials that meet international standards and enhance construction quality and efficiency. Omega-shaped studs are the ideal material to meet the needs of **high-end hotels, office buildings, large public facilities (such as airports, hospitals), and quality residential projects**.

2. Addressing Local Operational Challenges:

*User-Friendly Operation and Maintenance: Provides an **English** operation interface, technical manuals, and localized on-site training. The equipment design emphasizes durability and ease of maintenance to cope with potential power fluctuations.

*Powerful Local Support: We are committed to establishing a long-term service network with local partners, offering **installation supervision, operator training, timely spare parts supply, and remote technical support** to ensure the stable and continuous operation of the customer's production line.

**Primary Application Scenarios**

The Omega-shaped studs produced by this equipment are the preferred solution for the following applications:

*High-End Commercial Buildings: Ceiling and partition wall systems in large shopping malls, star-rated hotels, and modern office buildings.

*Critical Public Facilities: Internal framing and linings for airport terminals, hospitals, schools, and conference centers.

* Industrial and Logistics Buildings: Wall and roof systems for light industrial factories and warehouses, providing a clean and solid installation base.

*Modular and Rapid Construction: Suitable for modular building projects that have dual requirements for structural strength and construction speed.

We believe this Omega-shaped stud roll forming machine is a strategic partner that empowers Ethiopian partners to seize the golden period of construction and achieve industrial upgrading. If you have more specific information about target customers, we can provide tailored return-on-investment analysis or production line configuration plans.

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12 rows(As your requirement) |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5KW |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase(customizable) |

| Forming speed | 40-50m/min(The speed depends on the shape of the tile and the thickness of the material) |

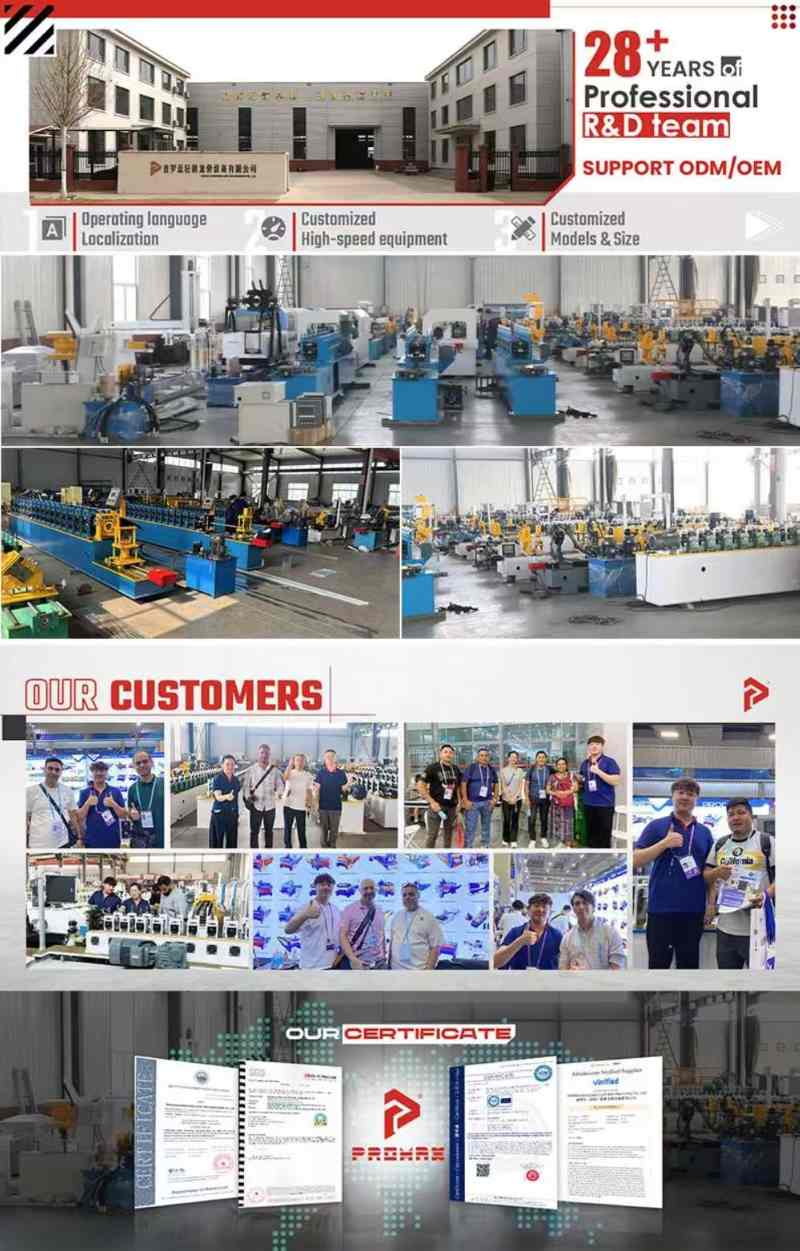

Why Choose Us

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

About Us

Haixing Industry Group – Precision Roll Forming Experts Since 1996

With nearly three decades of expertise, Haixing Industry Group specializes in designing and manufacturing high-performance roll forming machines and automated production lines. Trusted by over 5,000 clients in more than 150 countries, we turn custom requirements into reliable production solutions.

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.