WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

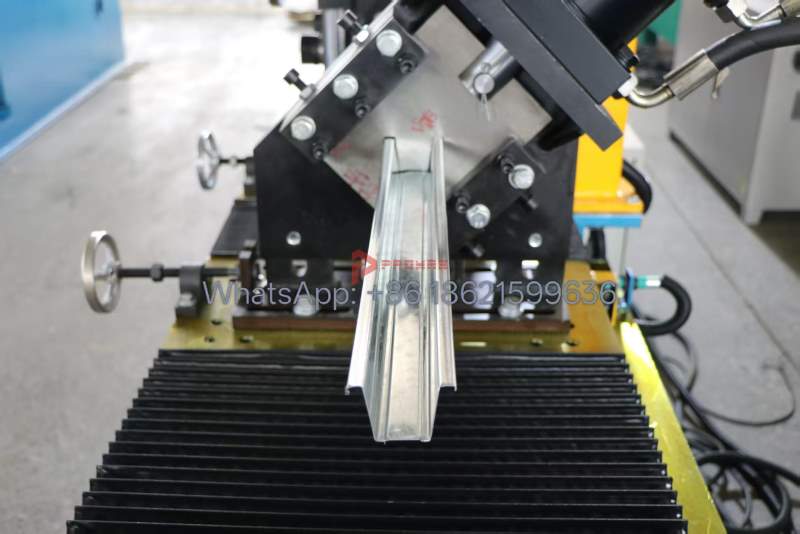

To meet the growing demand in Swaziland's construction, agricultural, and industrial sectors for high-strength, easily connectable structural components, we introduce this professional Furring channel machine. It is a precision track-type cold roll forming system specifically designed for producing three-dimensional studs with an Ω-shaped cross-section. It is the ideal choice for enhancing local building quality and industrial frame manufacturing efficiency.

Core Product: Omega (Ω) Track-Type Cold Roll Forming Machine

This machine is a multi-stand, high-precision track-type cold roll forming system dedicated to continuously and steadily rolling metal coil into stud products with a complex Ω-shaped cross-section.

*Unique Cross-Section Advantage: The produced Ω-shaped studs possess excellent bending and torsional resistance. Their unique curled-edge design facilitates quick snap-fit assembly with other components (like C/U studs), significantly improving construction efficiency.

*Wide Range of Applications: Perfectly suited for large industrial building roof purlins, agricultural greenhouse frames, storage rack uprights, and modern indoor ceiling systems in Swaziland, offering a lighter and more efficient solution than traditional angle steel.

Technical Highlights & Localized Adaptation

1. Robust and Stable Forming Capacity: The equipment employs a heavy-duty reinforced frame and high-rigidity forming roll shafts, ensuring stable and smooth operation even when processing thicker materials , adapting to Swanziland's diverse material supply conditions.

2. Intelligent & User-Friendly Operation: Standard with a PLC control system and variable frequency speed drive, enabling precise speed control and length cutting. The intuitive operation interface lowers the technical skill threshold for operators.

3. Targeted Durability Design: Critical components feature wear-resistant treatment and consider Swaziland's climatic and environmental factors, ensuring low failure rates and high reliability during long-term use.

Why is it a Fit for the Swaziland Market?

*Improves Building Quality: Ω-shaped studs provide more stable concealed support structures for large buildings, contributing to improved overall project quality and longevity.

*Promotes Agricultural & Industrial Development: Supplies core skeleton materials for building sturdier, wider-span agricultural greenhouses and industrial plants, supporting local production and construction.

*High Return on Investment: A single machine can meet the production needs for various high-end structural components, helping local manufacturers expand their business scope and enhance market competitiveness.

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12 rows(As your requirement) |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5KW |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase(customizable) |

| Forming speed | 40-50m/min(The speed depends on the shape of the tile and the thickness of the material) |

Why Choose Us

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

About Us

Haixing Industry Group – Precision Roll Forming Experts Since 1996

With nearly three decades of expertise, Haixing Industry Group specializes in designing and manufacturing high-performance roll forming machines and automated production lines. Trusted by over 5,000 clients in more than 150 countries, we turn custom requirements into reliable production solutions.

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.