WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Introducing the Advanced Strut Channel Roll Forming Machine

A strut channel roll forming machine is a highly specialized piece of industrial equipment designed for the continuous and precise manufacturing of metal strut channels, commonly known as C-shaped metal framing. The core function of the strut channel roll forming machine is to transform flat strips of pre-painted or galvanized steel into uniform C-profile channels through a cold-roll forming process. This efficient strut channel roll forming machine operates by progressively shaping the metal strip through a series of precision roller dies, each station contributing to the final cross-section. The automation and consistency provided by a modern strut channel roll forming machine ensure high-volume output with minimal material waste and exceptional dimensional accuracy. Furthermore, a well-engineered strut channel roll forming machine can be customized with various auxiliary units, such as precision decoilers, punching systems, cutting-to-length units, and automatic stacking equipment, to create a complete production line. Investing in a reliable strut channel roll forming machine is crucial for manufacturers seeking to produce sturdy and standardized support channels used extensively in construction, electrical installations, mechanical support, and HVAC systems. Ultimately, the productivity and quality of your metal framing products depend significantly on the performance of your strut channel roll forming machine.

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12 rows(As your requirement) |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5Kw |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase |

| Forming Speed | 40-50m/min(The speed depends on the shape of the tile and thickness of the material.) |

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

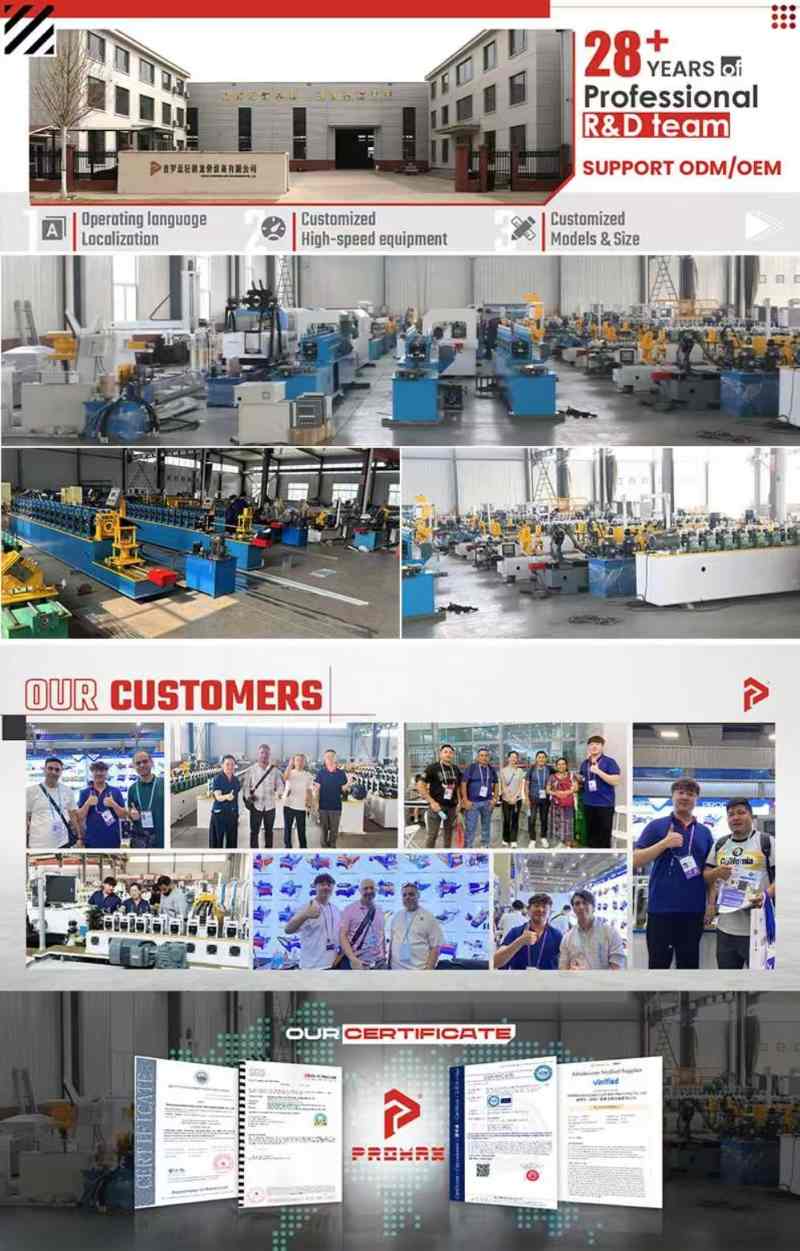

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.