WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

Equipment Overview and Core Advantages

This Steel stud and track roll forming machine is an intelligent production equipment that integrates digital control and flexible manufacturing technology. It is specifically designed for the efficient and precise production of C-shaped, U-shaped, and other stud components used in light-gauge steel structure construction. Its core advantages lie in:

Application Scenarios and Core Value

For the characteristics of Morocco's construction market, this equipment can deliver the following core value to contractors, prefabrication plants, and building material suppliers:

* Adapts to Diverse Project Needs: Particularly suitable for handling orders for light-gauge steel studs with variable specifications in projects such as residential complexes, tourist resort facilities, and commercial buildings, enabling rapid response to customization demands.

* Significantly Reduces Overall Costs: Reduces reliance on skilled technicians and minimizes errors from manual adjustments. Material utilization can reach over 98%, helping clients control total project costs.

* Enhances Production Capacity and Delivery Reliability: With a single machine's daily output reaching 4-6 tons, coupled with a stable mechanical structure and low-failure-rate design, it ensures on-time delivery for projects with tight schedules.

* Supports Local Industrial Upgrade: Assists Moroccan enterprises in transitioning towards an automated and digital advanced manufacturing model, enhancing their competitiveness in the North African market.

Localization Adaptations and Support

To better serve the Moroccan market, we offer the following targeted adaptations and services:

* Climate-Adaptive Design: The electrical cabinet is equipped with dust-proof and high-temperature heat dissipation modules. Core transmission components feature anti-corrosion treatment to adapt to the dry/dusty or coastal humid environments in some parts of Morocco.

* Energy and Standards Compliance: The equipment supports 220V/380V 50Hz standard voltage. Key safety specifications comply with CE standards, and the operation interface can be provided in French or Arabic based on client requirements.

* Localized Service Network: We have established technical service points with partners in Morocco, providing installation training, spare parts supply, and rapid on-site response to ensure continuous and stable equipment operation.

We look forward to cooperating with partners in Morocco to promote the adoption of light-gauge steel structure construction, offering comprehensive support ranging from equipment selection and technical training to production optimization.

| Formed Material |

GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.85mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12rows |

| Material of rollers | 45# steel |

| Cutter | Cr12 Mov |

| Power | 7.5+5.5KW |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3 Phase |

| Forming Speed | 40-50mm/min(The speed depends on the shape of the tile and the thickness of the material.) |

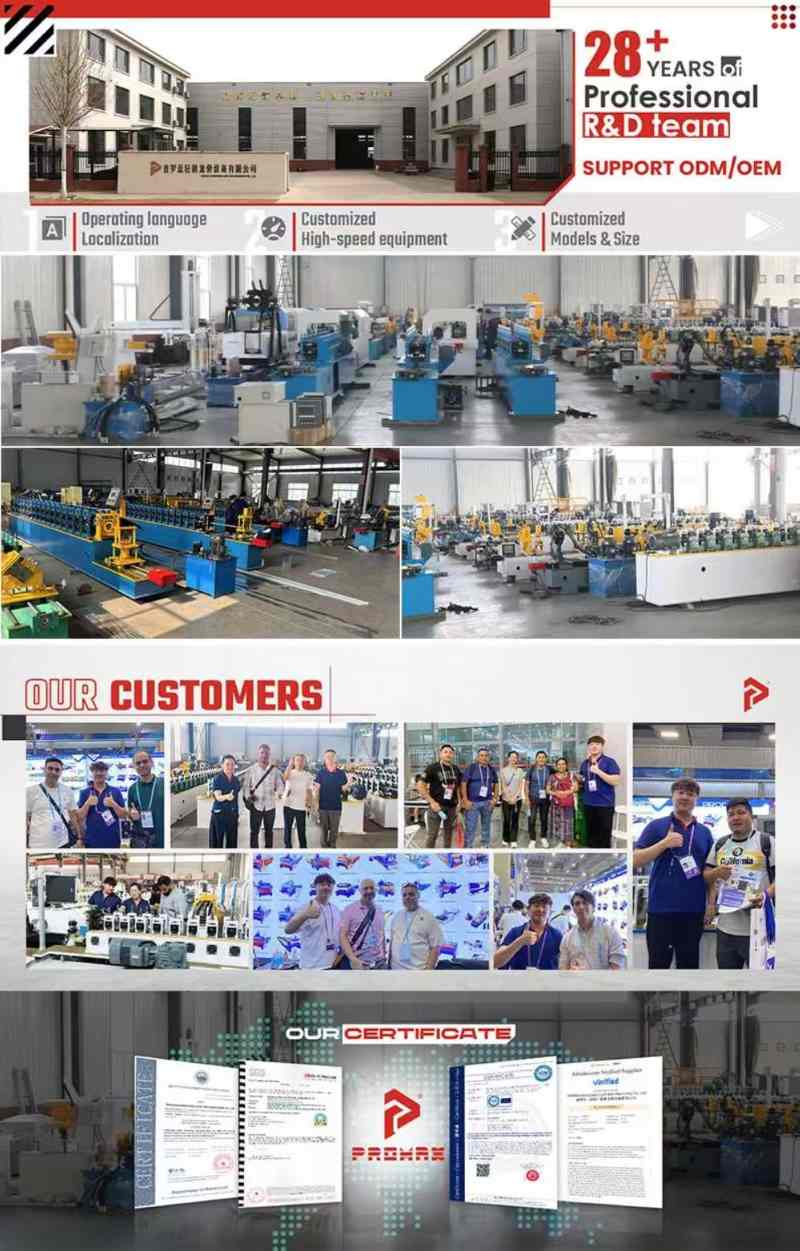

Why Choose Us

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

About us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.