WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

**Product Positioning and Core Advantages**

Designed for Ethiopia's infrastructure and mass housing market, the C channel making machine is a highly efficient and reliable fully automatic production equipment, dedicated to manufacturing the most widely used C-shaped studs in building partition and ceiling systems. As the most fundamental, high-volume standard component in light steel structures, C-shaped studs, with their proven design, economical cost, and high applicability, are key equipment for driving the scaled development of Ethiopia's construction industry.

**The core advantages lie in its exceptional stability and cost-effectiveness:**

*Proven Reliability and Durability: The equipment adopts a classic mechanical structure and control system validated by long-term market use. The core rolling dies are made of high-strength alloy steel, ensuring extremely low failure rates and a long service life during continuous production, providing customers with a stable return on investment.

*Efficient Production, Optimal Cost: The fully automated production line design allows for industry-leading speed from coil to finished product. The optimized design results in lower energy consumption and less material waste, making the comprehensive production cost per stud highly competitive, ideal for large-scale, standardized project demands.

*Easy Operation and Maintenance: The equipment logic is clear and relatively user-friendly for operators. The modular design makes daily maintenance and wear-part replacement very simple and fast, minimizing losses due to downtime.

This C-shaped stud machine is the "mainstay model" for entering Ethiopia's booming construction market:

1. Matches Large-Scale Construction Demands: Whether for government-led **large-scale social housing projects and industrial park factories**, or privately built **ordinary residences and shops**, C-shaped studs are the primary material for wall and ceiling framing. This equipment ensures local factories can provide a massive supply of standard components at stable, low cost, directly supporting national development plans like "affordable housing".

2. *Very Low Operational Barrier: We provide complete technical documentation, video tutorials, and on-site training in **English and Amharic**, ensuring the customer's team can quickly master production and maintenance skills. Localized spare parts inventory planning guarantees timely after-sales support.

**Primary Application Scenarios**

The C-shaped studs produced by this equipment form the "skeleton" of the following buildings:

*Residential and Apartment Buildings: Interior partition walls and ceiling studs for all types of housing.

*Commercial and Public Buildings: Internal framing systems for schools, clinics, office buildings, and retail stores.

*Industrial and Agricultural Buildings: Partitions and lining for light industrial factories and warehouses.

*Modular Housing: Used as structural wall framing for quickly assembled modular building units.

| Formed Material | GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.9mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12 rows(As your requirement) |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5Kw |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3Phase |

| Forming Speed | 40-50m/min(The speed depends on the shape of the tile and thickness of the material.) |

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

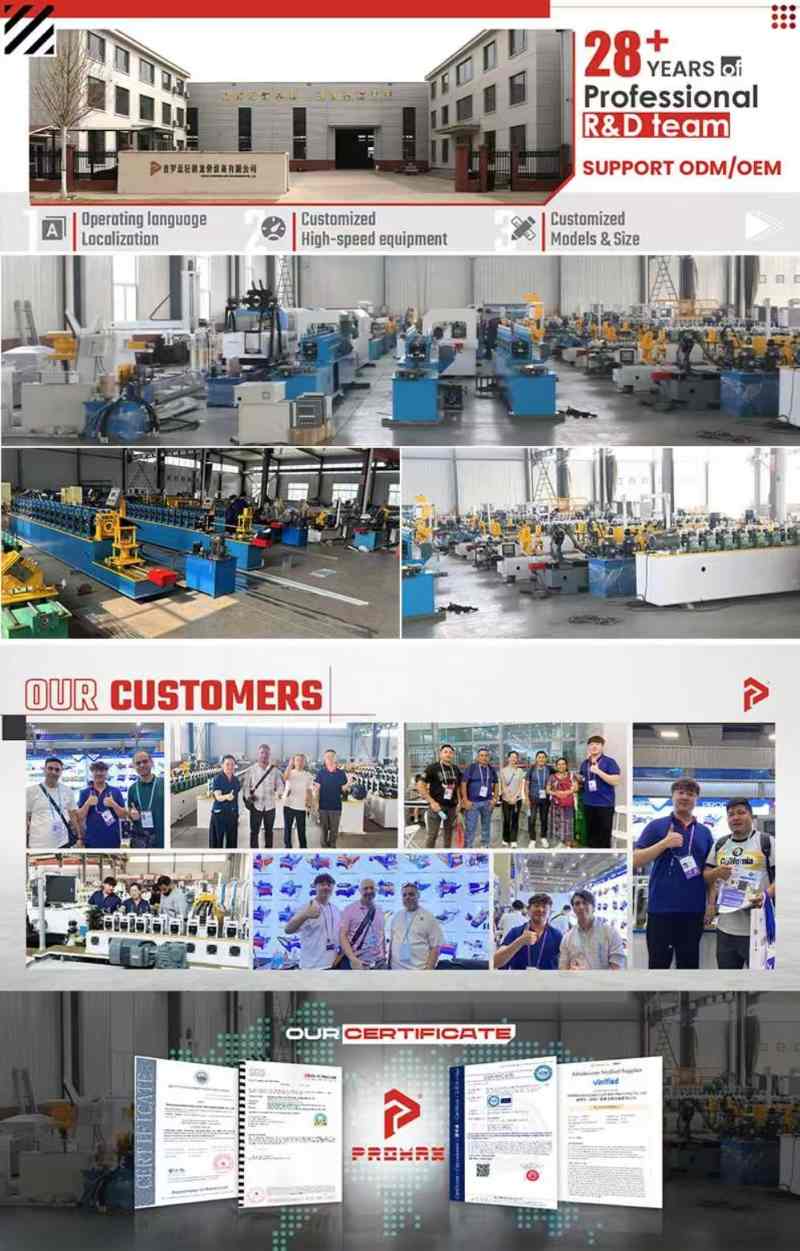

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.