WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

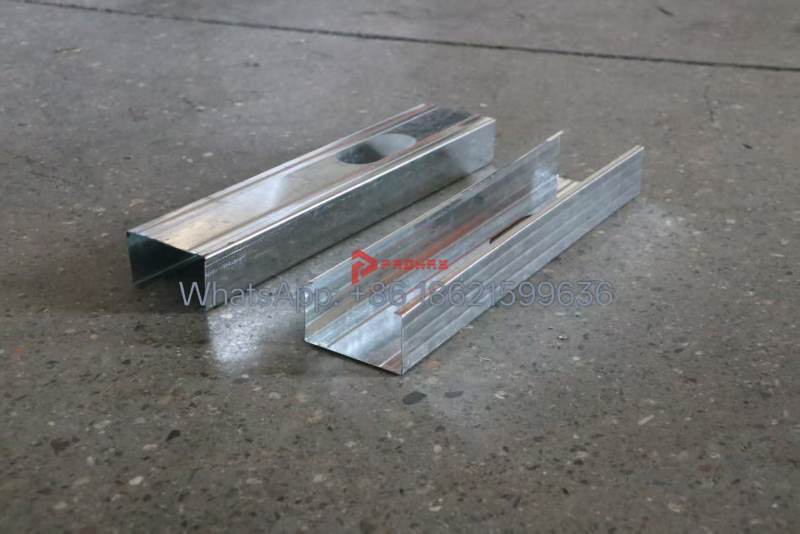

**Fully Automated Intelligent Model Change**: Simply enter or modify the specification dimensions at the control console and initiate the changeover. The equipment automatically completes all adjustments without manual intervention, capable of producing various specifications of studs such as C-type, U-type, and Usigma-type.

*Integrated Intelligent Processing: The equipment can import design data and automatically perform a series of actions like **punching, marking, and cutting** at corresponding positions, enabling continuous production from data to finished product.

*Remote Monitoring and Maintenance: Connected via a **4G module**, the equipment provides real-time feedback on production status, progress, and anomaly data to cloud servers and service personnel, supporting remote fault diagnosis and handling.

**Key Performance and Technical Specifications**

To ensure long-term stable operation, the equipment utilizes high-quality configurations for key components:

* Roller Shaft and Cutting System: The main shafts are made of high-strength **45# round steel**, and the roller wheels are treated with hard chrome plating and mirror polishing for high wear resistance. The cutting blades are made of **Cr12Mov** material with a design life exceeding 1 million cycles.

*Electrical Control System: The core control system employs high-precision **PLC** and frequency converters/electrical components from brands like **Schneider/Delta**, ensuring efficient, stable operation and low failure rates.

*Operation Method: Equipped with a **touch-screen operation interface**, allowing direct parameter input for one-touch automated production.

**Application Value and Market Suitability**

For construction and manufacturing enterprises in Panama, this equipment delivers tangible efficiency improvements:

*Enhances Production Efficiency and Flexibility: The rapid model-change capability allows flexible response to diverse orders, making it particularly suitable for producing light-gauge steel components for customized residential and commercial complex projects.

*Ensures Product Precision and Quality: Precise control throughout the entire process, from feeding and positioning to forming and cutting, guarantees accurate component dimensions and ensures subsequent construction quality.

*Optimizes Production Management: The real-time data feedback function enables managers to monitor production progress and equipment status anytime, anywhere, facilitating digital and transparent factory management.

**Why It Suits the Panama Market**

The features of this equipment align well with local demands in Panama:

*Addresses Diverse Construction Needs: With the rapid development of commercial and residential projects in areas like Panama City, the equipment's versatility and quick changeover capability can efficiently serve diverse production needs ranging from interior partitions to main structural components.

* Adapts to Operational Environment: The stable electrical system and remote operational support help reduce downtime under Panama's climatic conditions, ensuring production continuity.

*Drives Industry Upgrade: Introducing such intelligent equipment aids local manufacturers in transitioning towards automated, digital production, enhancing their competitiveness in the regional market.

In summary, this CU Fully Automatic Model-Change Stud Rolling Machine is not merely a tool for improving single-process efficiency but an intelligent solution that empowers partners in Panama to innovate their production models and seize opportunities in the prefabricated construction market.

| Formed Material |

GI/GL, PPGI/PPGL |

| Thickness | 0.45-0.85mm |

| Decoiler | Manual decoiler(will give you as free) |

| Roller station | 12rows |

| Material of rollers | 45# steel |

| Cutter | Cr12 Mov |

| Power | 7.5+5.5KW |

| Control system Language | English, Spanish, etc.(Support multiple languages) |

| Voltage | 380V, 50HZ, 3 Phase |

| Forming Speed | 40-50mm/min(The speed depends on the shape of the tile and the thickness of the material.) |

Why Choose Us

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

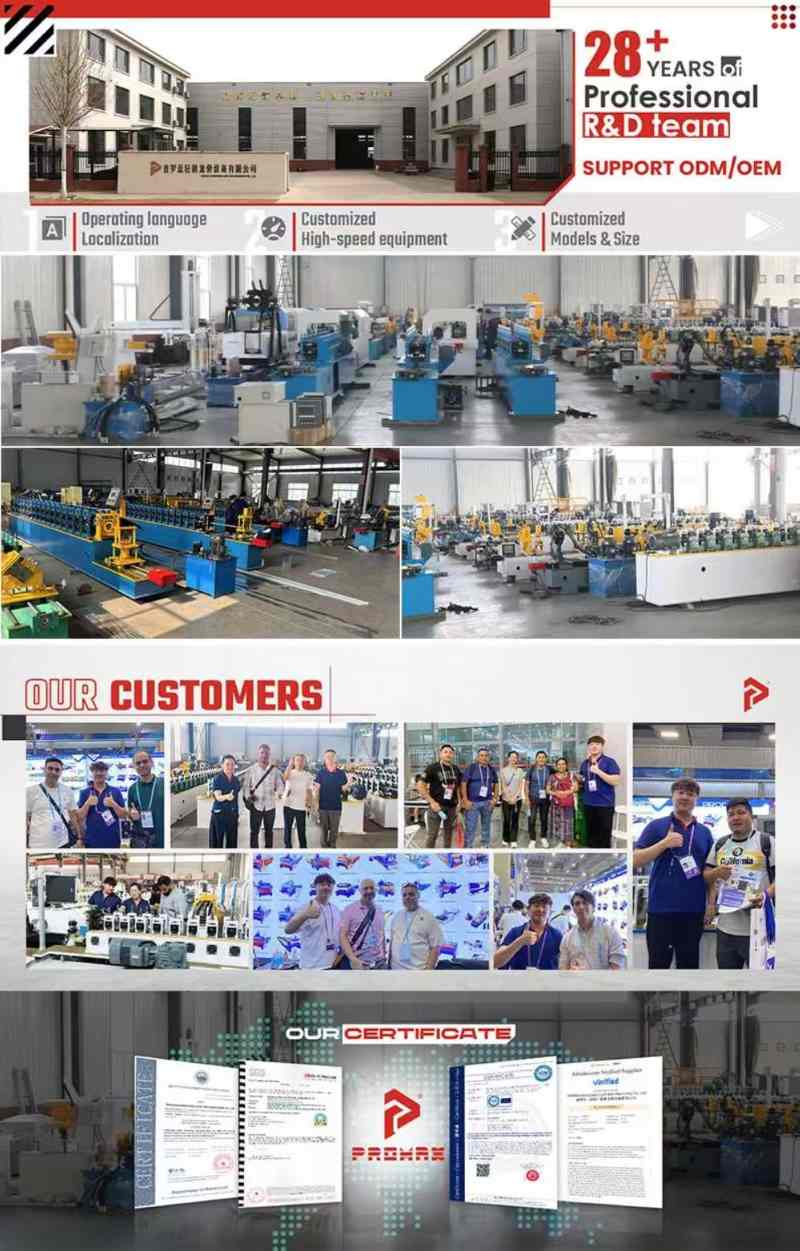

About us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.