WhatsApp:

E-mail:

Mobile Phone:

Tel:+86 022 86728681

Fax:+86 022 86728681

To meet the stable demand in Morocco's infrastructure, civil construction, and industrial framing sectors for fundamental structural profiles, we introduce this efficient and robust Angle Forming Machine (also known as an Angle Iron Roll Former). It is specifically designed for producing high-quality equal or unequal leg angle steel, serving as a core production asset supporting various construction projects across Morocco.

Core Product: Angle Forming Machine

This equipment is a high-performance cold roll forming machine that can continuously form metal coil into standard L-shaped cross-section angle steel.

*Fundamental & Critical: The produced angle steel is a basic and indispensable structural component in construction, power transmission towers, shelving, and machinery frames, offering wide-ranging applicability.

*High-Efficiency Production: Compared to traditional single-piece hot-rolling processes, this machine enables continuous, automated production of angle steel, significantly boosting efficiency and reducing raw material waste, making it suitable for large-scale project supply.

Technical Highlights & Localized Adaptation

1.Strong Material Adaptability: The sturdy forming frame and high-strength roll design can handle the common thickness range in the Moroccan market , meeting needs from light-duty decoration to heavy-duty support.

2.Stable Output Quality: The precision guidance system and stable transmission mechanism ensure the angle steel has accurate dimensions and excellent straightness, with full, crack-free right angles, guaranteeing the strength of the final structure.

3.Durability & Easy Maintenance: Key components are treated for wear and corrosion resistance. Considering the climate and working conditions in parts of Morocco, emphasis is placed on low failure rates and ease of maintenance to ensure long-term, stable operation.

*Supports Diverse Construction: Whether for modern buildings in Casablanca, emerging industrial zones in Tangier, or residential and agricultural facilities nationwide, angle steel is an essential raw material.

*Promotes Localized Manufacturing: Helps local manufacturers establish profile production capability, reducing dependence on imported formed angle steel, shortening supply chains, and enabling faster response to project demands.

*Clear Investment Value: The angle steel produced by the machine is a standardized, universal product with consistent market demand, offering investors reliable returns

| Formed Material |

GI/GL, PPGI/PPGL |

| Thickness |

1.35-2.0mm |

| Decoiler |

Manual decoiler(will give you as free) |

| Roller station | 8rows |

| Material of rollers | 45#steel, forging with chromium plate 0.05mm |

| Cutter | Cr12 Mov quenched treatment 58-60℃ |

| Power | 7.5+5.5KW |

| Control system Language | English, Spanish,etc.(Support multiple languages) |

| Voltage | 220V, 60HZ, 3Phase |

| Forming speed | 45m/min(The speed depends on the shape of the tile and the thickness of the material.) |

Why Choose Us

All-in-One Engineering Solutions

From initial concept to final production, we provide comprehensive support tailored to your needs.

Built to Last

Our machines are engineered for durability, delivering reliable performance over years of continuous operation.

Precision You Can Trust

Achieve consistent, micron-level accuracy in every product with our advanced roll forming technology.

Superior Materials

We use only premium-grade components to ensure strength, stability, and longevity.

Advanced Automation Systems

Equipped with cutting-edge electrical and control systems for enhanced efficiency and precision.

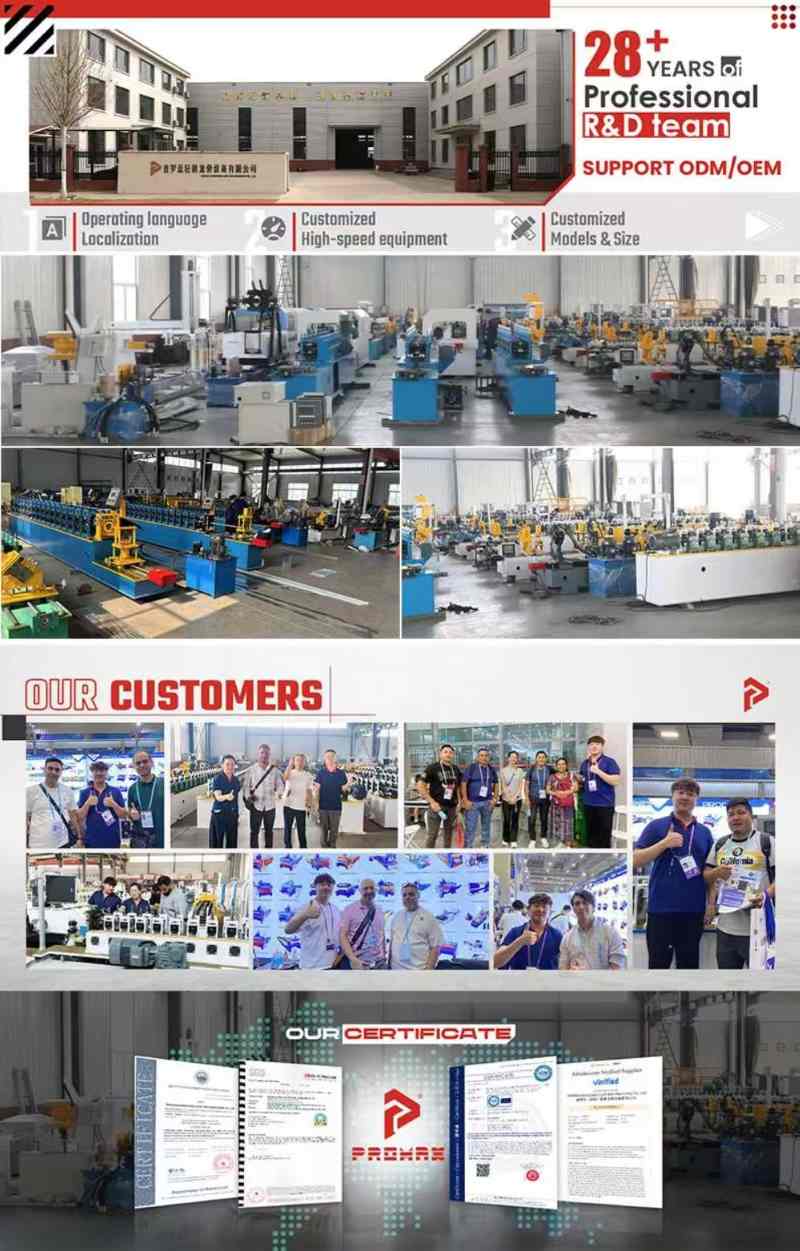

About Us

Since 1996 year, Promax Group main products have evolved from a standard keel roll forming machine to a customized automated high speed keel roll forming equipment production line, cooperating with 150+ countries & 5,000 + partners,always adhering to the concept of "honesty is our aim, win win is our pursuit", insisting on the service principles of "customer first, quality first, service first, after sales first", efficiently and professionally complete the products required by customers.